Welcome and hello!

As mentioned in a previous post, some sections of the book will cover specific topics, not in the chronological sequence of the other chapters. This is one of those sections. The story of Hunter Lumber is so integral to Charlie’s life that we’ve written it all together, right from the beginning through three generations. It’s divided into two parts here since it’s a long story with lots of anecdotes along the way! Maybe go and get yourself a cup of tea so you can settle in and enjoy.

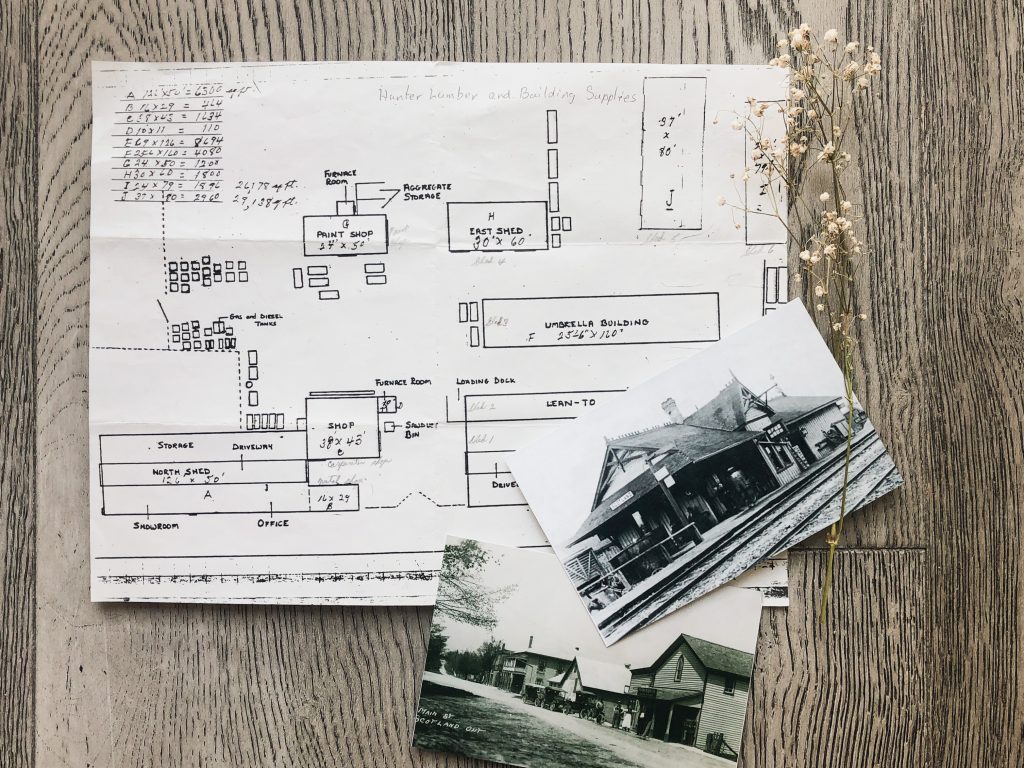

The parcel of land bordered by Oakland Road and Marcus Street in Scotland, on which the C.D. Hunter family had their home, had been owned by Marcus Malcolm in the early 1800’s and included a woolen mill on a pond. Kate’s father, Melvin Halliday, purchased this seven acre property (today known as 267 Oakland Road) to encourage Charles Dean and Kate to return to Scotland in 1922 and set up a business. This is where Charles Dean, Charlie’s father, began the lumber business. It started as a one man operation with limited supplies, and Kate kept the books.

“I remember playing in the lumberyard and falling off a pile of wood shingles which knocked me out. In grade one, I remember going with father to Harold and Goetz Lumber Yard to get a load of roofing. We backed into the shed and the truck stalled. The roofing was loaded. The train was backing on the siding and backed into the side of the truck and pushed it against the side of the lumberyard. The wooden cab was broken and some glass but we drove it home. Both of us were out of the truck and were unharmed. I remember having corn meal porridge for supper that night!“

From an early age I helped father in the business. After school and on Saturdays I was on hand to help. “I remember that father had his carpenter shop set up in the basement of the house before the shed was built. When he had to plane lumber he would hook the machinery up to the car motor (no electricity) and I would pass the lumber through the east basement window and take it out the west window after father had put it through the planer. Then it had to be turned around and put through again – west to east. One time father was sharpening some equipment for the feed mill on Queen Street. He put an emery stone on the saw mandrel to do the sharpening. Too much speed caused it to explode. One piece hit his right thumb and two others went over his head and hit the beams in the ceiling. Father’s thumb was badly injured, and the surgeon wanted to remove the whole thumb, but Dr. Anderson said “no”, and put it back together. His thumb healed and was in use for the rest of his life.“

“I remember going with father to Clubine Lumber for honey bee supplies, and going to see a factory that made pre-fab houses. I remember that the first forklift was on the back of a tractor, and that Herb Malcolm worked occasionally to unload box cars of lumber. My dog, a white Spitz dog, would not let Herb into the yard!“

As the business grew, an office on the north west corner was built in 1923, which had a wood stove for heat. Next, the shed with the driveway to the east was built for storage of lumber. Lumber and cement would be brought in by boxcars to the Scotland TH&B (Toronto Hamilton & Buffalo) station, a mile east on Oakland Road. The boxcars were unloaded by hand onto a truck and brought up to the lumberyard. (One time, while driving up the lower driveway by the house with a loaded truck, the lumber slid off the back end.) Often it was evening work, and Herb Malcolm was hired as extra help. Demurrage was charged if the cars were not unloaded in three days.

In the early days, Father built tourist cabins and chicken houses in the lumberyard. The cabins went to Renton. He would deliver them on a truck or by electric train at Oakland on the Lake Erie and Norfolk (LE&N) line. Father supplied the building materials to construct the Scotland Continuation School which opened in 1924, and the material for the Woodbury School too.

“In my late teens, I trucked two loads of greenhouse glass from Toronto in a day. At sixteen I was driving the truck with a load of cedar boards for bee supplies to Troy, Ontario, when the load started to shift off the back end. At a service station on the corner of Highway 24 and 99, I backed up to a hydro pole and pushed the 20 foot lumber back on the 12 foot platform and continued on my way.”

“On July 4, 1937, my father, Hugh Spencer and I built 3 to 4 kilns for Ross Courtnage, Fairfield. After that we contracted the jobs out to building crews.” ( Kate’s diary) One year, the crew was 45 men strong with George Tuscok as boss.

In 1939 I started to work full time in the business. Then, in 1946, from January to April, I took a Drafting & Construction course at Central Technical School in Toronto. While there, I boarded with my cousin Edwin Bronson and his wife, Miriam. “When I arrived home on April 18th, I was put to work unloading lumber at the station with Morley Wheeler, Ensley Graves and Don Eddy!”

In the 1940’s farmers had begun to grow tobacco and I drew up construction plans for greenhouses, kilns and barns. Farmers needed greenhouses to start the plants, kilns to cure the leaves, and barns to store the cured tobacco before it was sold. This farm construction kept the yard busy delivering material to the building sites. During the tobacco years the company prepared (grooved) greenhouse rafters from September to March as the greenhouses had to be constructed by March 1. Material for kilns was delivered March through September. We built farm buildings all through the 40’s and 50’s. When the kilns started being made with metal, and not wood frame, we switched to building houses instead of farm buildings. Often I would do the drawing for a house or modify an existing one, and Walter Krauter and gang did the building.

On June 1, 1947, my sister Mary left her job at Universal Cooler in Brantford to take over looking after the books from Mother who had kept the books for 25 years. In 1951 a partnership was formed between Father, Mary and I. And on June 23, 1959, the business was incorporated as Hunter Lumber and Building Supplies.

So incredibly interesting! Stay tuned for the rest of the story next time!

xo

andrea